Avicenna J Environ Health Eng. 11(1):33-38.

doi: 10.34172/ajehe.5496

Original Article

Generation of Biogas Using Cow Dung With Organic Waste in the Presence of Iron Filings

Mangala Gowri D.P 1, *  , Rashma Shetty 2

, Rashma Shetty 2

Author information:

1MTech Student, Environmental Engineering, UBDT College of Engineering, Visvesvaraya Technological University, Davangere-577004, Karnataka, India

2Department of Civil Engineering, UBDT College of Engineering, Visvesvaraya Technological University, Davangere-577004, Karnataka, India

Abstract

In recent years, major issues such as demographic growth, food security, and exploitation of natural resources have raised worries worldwide. To handle these issues and the environment in an eco-friendly manner, a shift has been made from the mere exploitation of natural resources to their recovery and reuse. The production of organic waste is increasing dramatically. Anaerobic digestion (AD) with related biogas production is regarded as a substitute for waste management strategies such as landfilling and incineration of municipal solid waste (MSW). Biogas systems protect air, water, and soil by recycling organic waste into renewable energy and soil products while reducing greenhouse gas emissions. The present study aimed to establish a biogas system that involves co-digestion and iron filings. Specifically, it investigated the AD of vegetable waste combined with cow dung and Jatropha seed cake with iron filings. The experiment was conducted over 60 days by four digesters (S1, S2, S3, and S4) containing mixtures of cow dung and vegetable waste (S1), cow dung and Jatropha seed cake (S2), cow dung and vegetable waste with 10 g of iron filings (S3), and cow dung and Jatropha seed cake with 10 g of iron filings (S4). After 60 days, the amount of biogas collected from the digesters S1, S2, S3, and S4 was 172.9 mL/gVS, 205.64 mL/gVS, 186.086 mL/gVS, and 231.25 mL/gVS, respectively. The sample mixture of digester S4, which contained cow dung and Jatropha seed cake with iron filings, resulted in the maximum yield of biogas production due to the iron additive potential for accepting and donating electrons.

Keywords: Biogas, Anaerobic digestion, Vegetable waste, Jatropha seed cake, Iron filings,

Copyright and License Information

© 2024 The Author(s); Published by Hamadan University of Medical Sciences.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (

https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Please cite this article as follows: Gowri D.P.M, Shetty R. Generation of biogas using cow dung with organic waste in the presence of iron filings. Avicenna J Environ Health Eng. 2024; 11(1):33-38. doi:10.34172/ajehe.5496

1. Introduction

Energy is a critical element for a country’s economic and social development, facilitating both residential and industrial operations. Two primary sources of energy are renewable and non-renewable energy. Renewable energy sources (e.g., solar, wind, tidal, and geothermal) can be replenished quickly, are inexpensive, and are environmentally beneficial (1), whereas non-renewable energy takes a long time to refill, cause environmental degradation, and are about to deplete (2). Due to the high level of industrialization, energy demand has reached a point where the available sources cannot fulfill the increasing demand. Furthermore, the rising cost of fossil fuels such as gasoline, kerosene, and diesel has prompted people in rural and urban areas to seek alternative sources of fuel for energy generation. This has resulted in ongoing tree cutting for fuel, resulting in widespread deforestation and environmental deterioration, which is now a global concern (3). Bioenergy briquetting, solar and wind energy, pelletization, combustion of bioenergy residues, and biogas production are all alternatives to wood fuel (4).

Solid waste management (SWM) has become a major problem in urban areas. Changes in lifestyle, consumer tradition, and economic development led to major problems in present-day societies (5). As a result of the steady population growth, industrialization, and urbanization, the generation of municipal solid waste (MSW) has increased over the past decade (6). Solid waste significantly contributes to microplastics in the environment, including those found in landfill refuse, sludge, and food waste. The increasing distribution of microplastic (100 nm-5 mm) across various ecosystems is currently a major environmental concern (7). According to the Annual Report on SWM (2020-21) by the CPCB, Delhi, India generates 160 038.9 tonnes of solid waste per day (TPD), of which 152 749.5 TPD is collected, 79956.3 TPD is treated, and 29427.2 TPD is landfilled. Additionally, 50 655.4 TPD of the total generated waste remains unaccounted for. In various zones of India, the composition of MSW ranged from 40%-60% organic solids and 10%-25% recyclable waste. The moisture content was observed to vary from 30% to 60%, while the C: N ratio was observed to be in the range of 20-40 (8).

A change from the use of natural resources to their recovery and reuse is necessary to address these problems sustainably (9). As an effective and practical waste stabilization method, anaerobic digestion (AD) transforms dilute solid waste into sustainable energy with organic fertilizers. AD has noticeable application potential for agriculture and the environment for sustainability (10). The properties of raw materials and economic considerations are important for designing and operating digesters (11). A few studies conducted on AD of Jatropha seed cake reported that Jatropha seed cake can yield 355 L of biogas per kg of cake, with a methane content of 70% (12). Moreover, Jatropha seed cake could produce 60% more biogas compared to cattle dung. This study sought to systematically examine the effect of iron filings as an additive in AD. It aimed to provide practical conditions for biofuel generation from AD of diverse waste sources, including vegetable waste, Jatropha seed cake, and cow dung with iron filings. Anaerobic substrates were processed to generate biogas, and total solid (TS), pH, volatile solid (VS), and chemical oxygen demand (COD) were measured. Examining these parameters will contribute to the establishment of a biogas system using accessible vegetable waste and other substrates.

2. Materials and Methods

2.1 Materials

The experiment used four 20-L plastic containers, rubber seals, gas pipes, and hose clips. Table 1 presents a list of substances and other relevant data from the experiment.

Table 1.

Table of Raw Materials and Other Data

|

Sl. No

|

Items

|

Description

|

| 1. |

Raw materials used |

Cow dung, Jatropha seed cake, Vegetable waste |

| 2. |

Fermentation |

Anaerobic digestion |

| 3. |

Additives |

Iron filings |

| 4. |

Gas collection method |

Water displacement method |

2.2 Methods

2.2.1. Sample Collection

Vegetable waste samples were gathered from the UBDT College of Engineering canteen, while Jatropha seeds cake was collected from a business location in Chandigarh.

2.2.2. Construction of Digester

The experiment used digesters made from acrylic bottles with a 20L capacity, a diameter of 5 cm, and a height of 25 cm. The number of diameters was four. Moreover, four glass bottles with a 3 L capacity each were used to store the water, and four plastic bottles with a 1 L capacity were utilized to collect water displaced from the glass bottles. A 4 m × 1 cm diameter pipe was used to transfer the gas produced in the digester. M seals with additional pipe were provided for the lid at the top right side of the digester to maintain the digester in an airtight position and to adjust the pH.

2.2.3. Feedstock Preparation

Fresh organic waste (i.e., cow dung, vegetable waste, and Jatropha seed cake) was employed as a source of food for biological digesters. In the laboratory, these materials were distributed and mixed properly before being added to the digesters.

2.2.4. Inoculums

Three different types of sources were involved in this study: Cow dung, Jatropha seed cake, and vegetable waste.

Digester 1 (S1): Comprises cow dung and vegetable waste in a 1:1 ratio, mixed with water.

Digester 2 (S2): Comprises cow dung and Jatropha seed cake in a 3:1 ratio, mixed with water.

Digester 3 (S3): Contains a mixture of cow dung and vegetable waste with 10 g of iron filings.

Digester 4 (S4): Comprises a mixture of cow dung and Jatropha seed cake with 10 g of iron filings.

2.3 Experimental Procedure

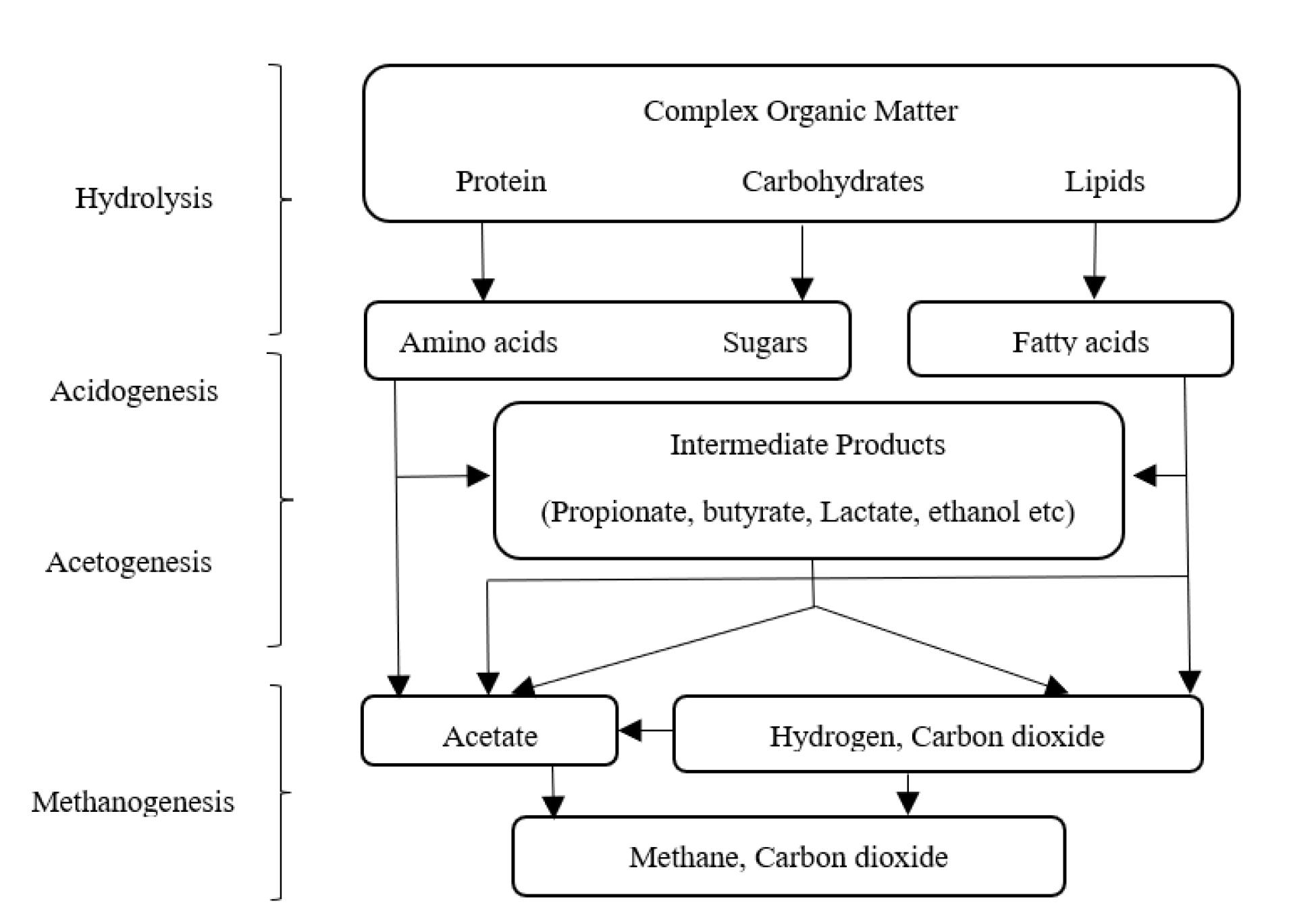

This study estimated the mesophilic decomposition of organic matter with and without iron filings. Considering that the bulk density of the solids is almost equal to the density of the water, substance saturation was calculated as the weight of solids/total volume of water plus solids. Four digesters operated continuously at a capacity of 20 L with an efficient volume of 15 L as depicted in Figs. 1 to 4. After filling the inoculums inside the digesters, the slurries were blended with a stirrer and allowed to settle. This experiment was carried out for 60 days, from June to August. Weekly, liquid samples from the digestors were obtained and tested for VS, TS, and COD, while pH was tested every two days. Sodium hydroxide or acetic acid, which promotes methanogen development, was used to maintain a pH of 6.5-8.5. The water displacement method was employed to calculate biogas generation. Fig. 5 shows AD stages.

Fig. 5.

AD Stages (13). Note. AD. Anaerobic digestion

.

AD Stages (13). Note. AD. Anaerobic digestion

3. Results and Discussion

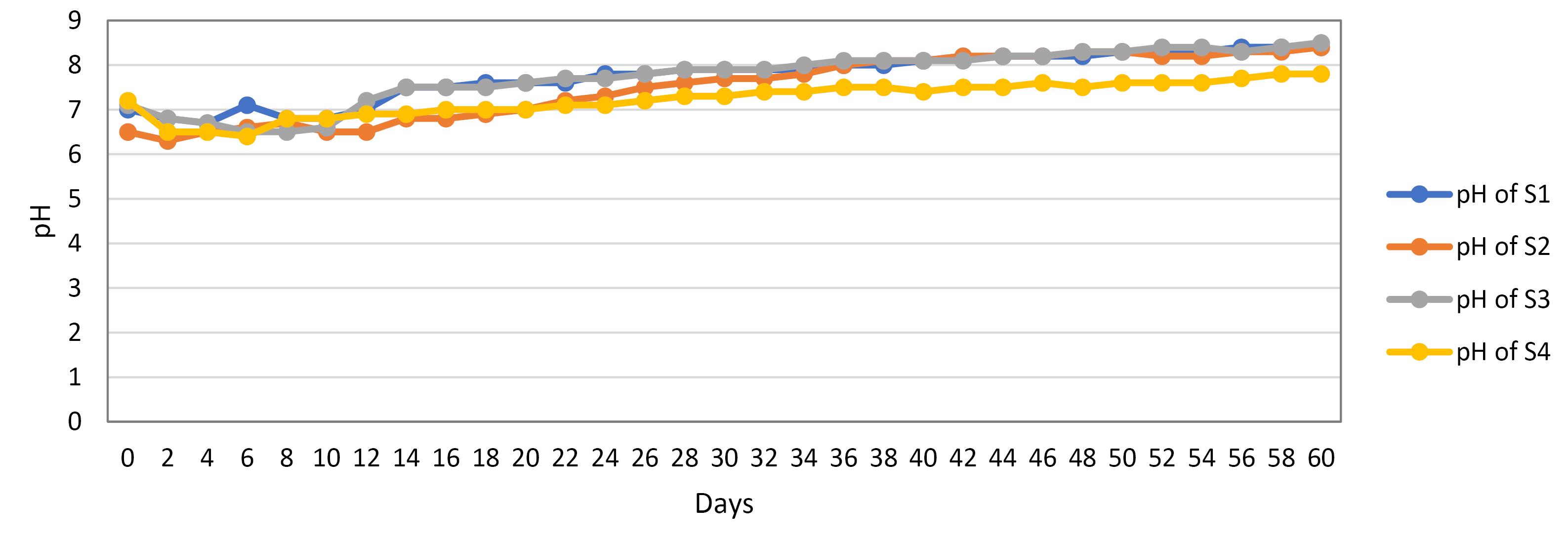

The experiment was conducted over 60 days, and the pH was measured every two days. The TS, VS, and COD were examined every 7 days for the slurry. Fig. 6 illustrates the pH variation for digesters S1, S2, S3, and S4. The initial pH was about 7, 6.5, 7.1, and 7.2 for digesters S1, S2, S3, and S4, respectively. After the second day, the pH began to drop due to acid generation in digesters. Afterward, the pH began to rise, reaching 8.4, 8.4, 8.5, and 7.8 in digesters S1, S2, S3, and S4, respectively on the 60th day. This rise can be attributed to the activity of methanogenic microorganisms resulting in the production of alkaline substances as byproducts and a subsequent rise in pH (14).

Fig. 6.

Comparison of pH for Digesters

.

Comparison of pH for Digesters

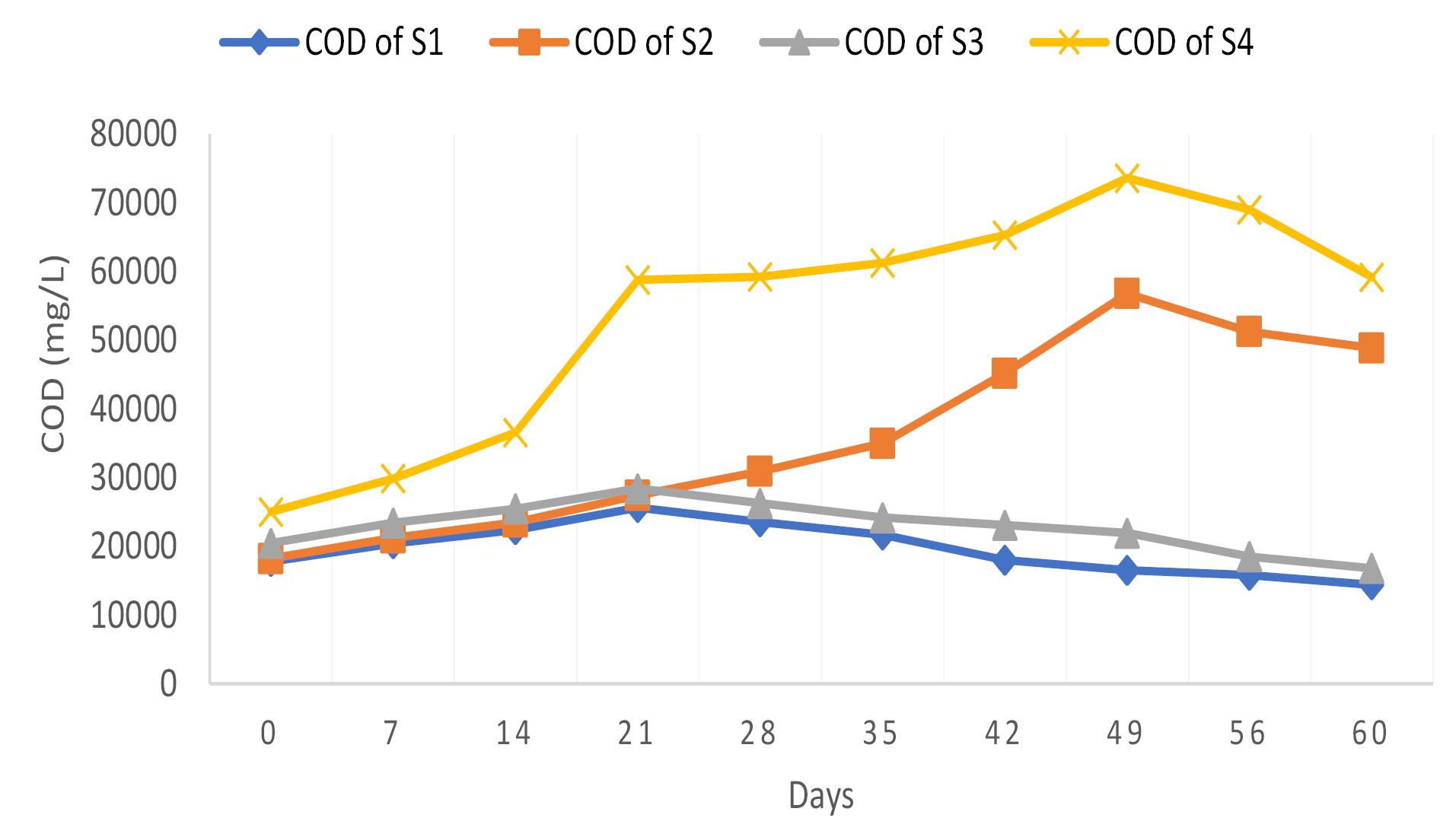

Few researchers reported that a pH range of 5.0 to 6.0 is suitable for acidogenic, while a pH from 6.5 to 8.0 is more convenient for the methanogens group (15). Fig. 7 represents the COD reduction for digesters S1, S2, S3, and S4. It is observed that the COD was higher in the digester S4 compared to S1, S2, and S3. The COD of all four digesters rose initially due to the establishment of the microbial community and organic matter breakdown. The COD levels of digesters S1 and S3 dropped after 21days, while those of digesters S2 and S4 dropped after 49 days because the digestion process progressed and the microbial population became more efficient. The COD level typically decreases as organic materials are converted into biogas and other byproducts (16). This study achieved COD removal efficiency within the optimum range.

Fig. 7.

Comparison of COD for Digesters. Note. COD: Chemical oxygen demand

.

Comparison of COD for Digesters. Note. COD: Chemical oxygen demand

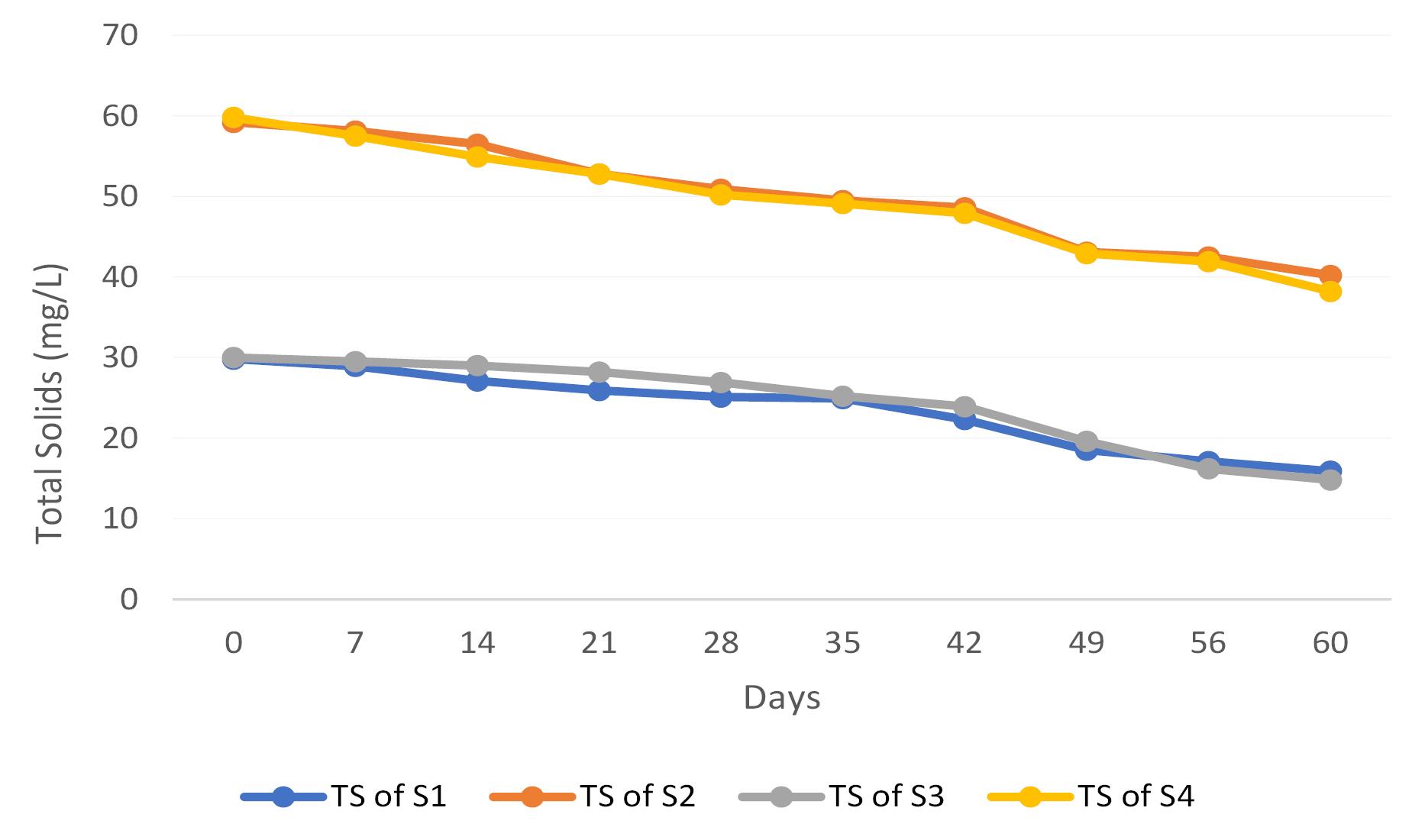

Fig. 8 depicts the variation of TS for digesters S1, S2, S3, and S4. On the first day, the TS levels of the digesters were measured and recorded as 29.8 mg/L, 59.2 mg/L, 30 mg/L, and 59.8 mg/L, respectively. TS was found to continuously reduce to 15.9 mg/L, 40.2 mg/L, 14.8 mg/L, and 38.2 mg/L, respectively, by the 60th day. This reduction is due to the degradation of organic substances present in the digesters and the conversion of solids into biogas and liquid byproducts in the digester (17). This study achieved TS removal efficiency within the optimum range.

Fig. 8.

Comparison of TS for Digesters. Note. TS: Total solid

.

Comparison of TS for Digesters. Note. TS: Total solid

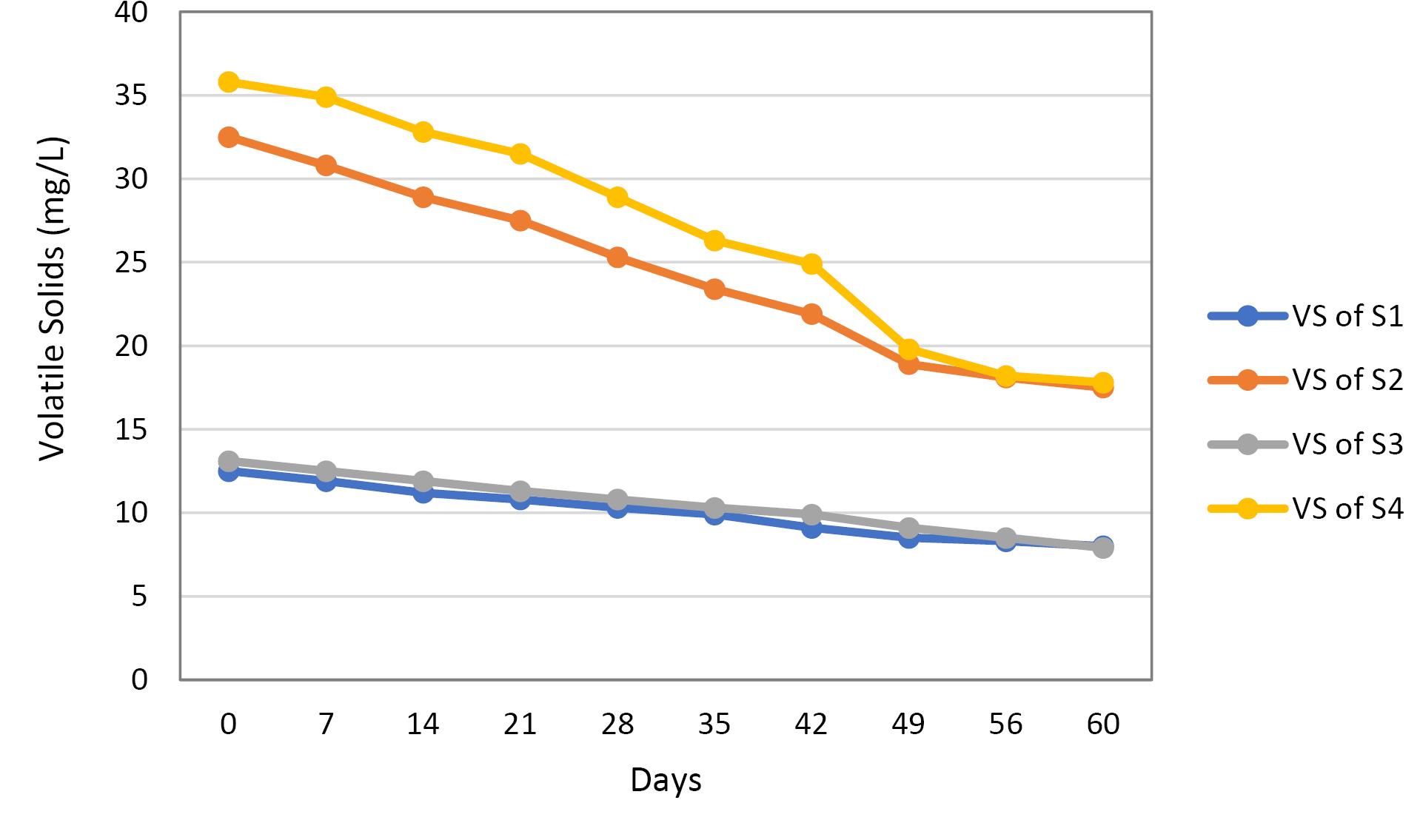

Fig. 9 displays the variation of VS for digesters S1, S2, S3, and S4. Initially, VS levels were recorded to be 12.5 mg/L, 32.5 mg/L, 13.1 mg/L, and 35.8 mg/L, respectively. Then, VS levels declined continuously to 8 mg/L, 17.5 mg/L, 7.9 mg/L, and 17.8 mg/L by the 60th day due to the degradation of organic content in the digesters and microbial activity (18).

Fig. 9.

Comparison of VS for Digesters. Note. VS: Volatile solid

.

Comparison of VS for Digesters. Note. VS: Volatile solid

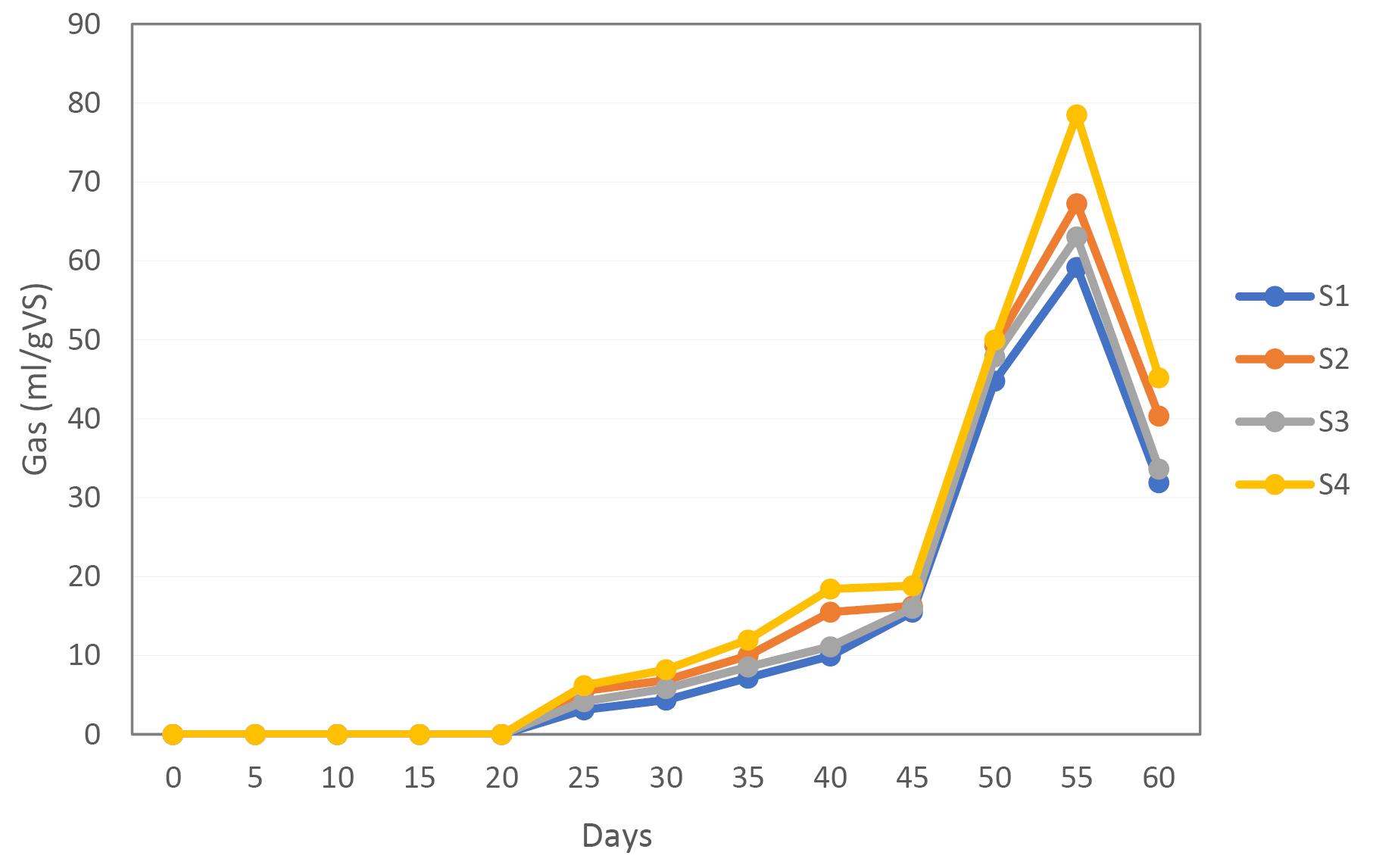

3.1. Cumulative Gas Production from the Digesters

The total cumulative biogas readings are displayed in Fig. 10. On the 60th day, the digesters produced total cumulative biogas levels of 172.9 mL/gVS, 205.64 mL/gVS, 186.086mL/gVS, and 231.25 mL/gVS in reactors S1, S2, S3, and S4, respectively. The breakdown of substrates began after the 20th day in all reactors. As evident in Fig. 10, the produced biogas was higher in the digester S4 (mixture of cow dung, Jatropha seed cake, and iron filings) compared to the other three digesters (3). This increase is due to the iron filings, which promote the breakdown of organic matter into methane and carbon dioxide, accelerating the AD process and leading to more efficient biogas production. Few studies reported similar findings, that is, the presence of iron filings in AD causes higher biogas generation (19).

Fig. 10.

Cumulative Gas Production in the Digesters

.

Cumulative Gas Production in the Digesters

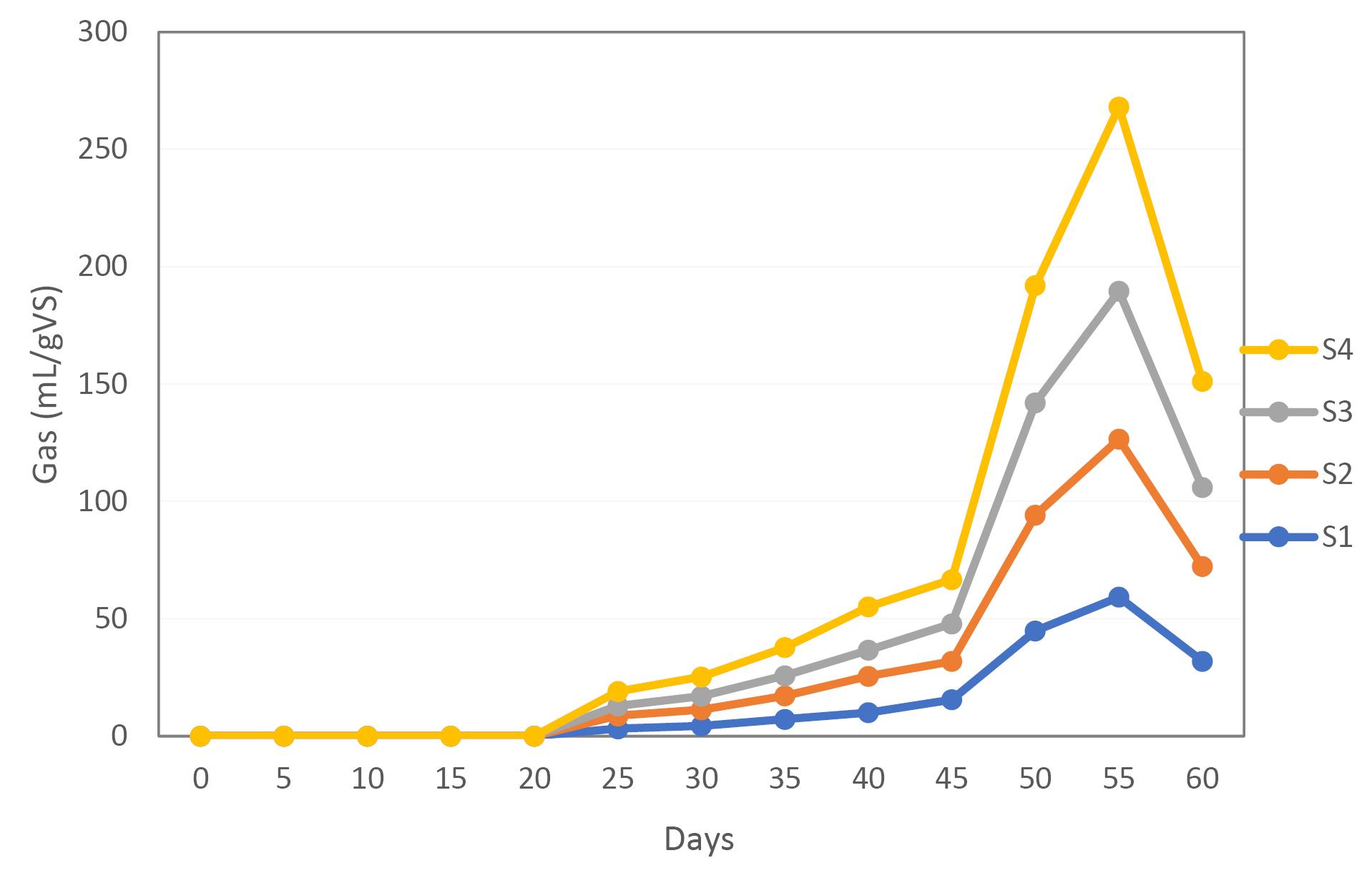

3.2. Comparison of Total Biogas Produced in All Digesters

Fig. 11 compares the total biogas produced in all digesters (S1, S2, S3, and S4) over 60 days. The highest biogas generation occurred in the digester containing a mixture of cow dung, Jatropha seed cake, and iron filings (Digester S4). This is attributable to the iron additives’ excellent capacity to accept and donate electrons (3), which alleviates the decrease in pH and elevates COD concentration in the effluent. Additionally, the presence of iron filings enhances the interaction of organic substrates with methanogens, promoting biogas release through a bio-stimulating mechanism and facilitating the digestion of organic waste.

Fig. 11.

Comparison of Gas Produced in All the Biogas Digesters

.

Comparison of Gas Produced in All the Biogas Digesters

4. Conclusion

The study revealed that initial substrate properties such as pH, organic loading rate, hydraulic residence period, and temperature, as well as substrate addition directly affect gas production. The biogas generated in all digesters were recorded as 176.9 mL/gVS, 205.64 mL/gVS, 186.086 mL/gVS, and 231.25 mL/gVS in digesters S1, S2, S3, and S4, respectively. Furthermore, the highest biogas was produced in the digester S4, which contained a mixture of cow dung, Jatropha seed cake, and iron filings. Comparing digesters, digesters S3 and S4 (both containing iron filings) were found to produce higher biogas than digesters S1 and S2. Among all the improvement alternatives, iron-based additions have been highlighted as effective in boosting the AD process productivity due to their electron uptake and donating capacities. Excessive TS can potentially reduce microbial activity and slow down biogas production, while an adequate VS content ensures a higher biogas yield. By maintaining the pH within the range of 6.8-8.5, higher biogas production can be achieved; therefore, the pH should be kept within this range.

Acknowledgments

This research experiment was carried out at the Environmental Laboratory of UBDT College of Engineering, Davangere, Karnataka. The authors extend their gratitude to all those who contributed directly and indirectly to this project.

Authors’ Contribution

Conceptualization: Mangala Gowri D.P, Rashma Shetty.

Data curation: Mangala Gowri D.P, Rashma Shetty.

Formal analysis: Mangala Gowri D.P.

Investigation: Mangala Gowri D.P.

Methodology: Mangala Gowri D.P.

Project administration: Rashma Shetty.

Resources: Mangala Gowri D.P, Rashma Shetty.

Supervision: Rashma Shetty.

Competing Interests

None declared.

References

- Ahamed JU, Raiyan MF, Hossain MS, Rahman MM, Salam B. Production of biogas from anaerobic digestion of poultry droppings and domestic waste using catalytic effect of silica gel. Int J Automot Mech Eng 2016; 13(2):3503-17. [ Google Scholar]

- Eliyan C. Anaerobic Digestion of Municipal Solid Waste in Thermophilic Continuous Operation [dissertation]. Thailand: Asian Institute of Technology School of Environment, Resource and Development; 2007. p. 1-149.

- Adekunle AS, Ibitoye SE, Omoniyi PO, Jilantikiri LJ, Sam-Obu CV, Yahaya T. Production and testing of biogas using cow dung, Jatropha and iron filins. J Bioresour Bioprod 2019; 4(3):143-8. doi: 10.12162/jbb.v4i3.002 [Crossref] [ Google Scholar]

- Nair VV, Kumar P, Thalla AK, Dhar H. Methane production from anaerobic digestion of organic fraction in municipal solid waste. In: International Conference on Sustainable Energy and Built Environment (ICES); 2015; Vellore, Tamil Nadu. p. 677-82.

- Men Y, Zheng L, Zhang L, Li Z, Wang X, Zhou X. Effects of adding zero valent iron on the anaerobic digestion of cow manure and lignocellulose. Front Bioeng Biotechnol 2020; 8:590200. doi: 10.3389/fbioe.2020.590200 [Crossref] [ Google Scholar]

- Farghali M, Andriamanohiarisoamanana FJ, Ahmed MM, Kotb S, Yamamoto Y, Iwasaki M. Prospects for biogas production and H2S control from the anaerobic digestion of cattle manure: The influence of microscale waste iron powder and iron oxide nanoparticles. Waste Manag 2020; 101:141-9. doi: 10.1016/j.wasman.2019.10.003 [Crossref] [ Google Scholar]

- Amobonye A, Bhagwat P, Raveendran S, Singh S, Pillai S. Environmental impacts of microplastics and nanoplastics: a current overview. Front Microbiol 2021; 12:768297. doi: 10.3389/fmicb.2021.768297 [Crossref] [ Google Scholar]

- Central Pollution Control Board (CPCB). Annual Report on Solid Waste Management (2020-21). Delhi: CPCB; 2016.

- Sen K, Mahalingam S, Sen B. Rapid and high yield biogas production from Jatropha seed cake by co-digestion with bagasse and addition of Fe2+. Environ Technol 2013; 34(21-24):2989-94. doi: 10.1080/09593330.2013.798000 [Crossref] [ Google Scholar]

- Ogunkunle O, Olatunji KO, Jo A. Comparative analysis of co-digestion of cow dung and Jatropha cake at ambient temperature. Journal of Fundamentals of Renewable Energy and Applications 2018; 8(5):271. doi: 10.4172/2090-4541.1000271 [Crossref] [ Google Scholar]

- Raheman H, Mondal S. Biogas production potential of Jatropha seed cake. Biomass Bioenergy 2012; 37:25-30. doi: 10.1016/j.biombioe.2011.12.042 [Crossref] [ Google Scholar]

- Chandra R, Vijay VK, Subbarao PMV, Khura TK. Production of methane from anaerobic digestion of Jatropha and Pongamia oil cakes. Appl Energy 2012; 93:148-59. doi: 10.1016/j.apenergy.2010.10.049 [Crossref] [ Google Scholar]

- Ramatsa IM, Akinlabi ET, Madyira DM, Huberts R. Design of the bio-digester for biogas production: a review. In: Proceedings of the World Congress on Engineering and Computer Science; 2014; San Francisco, USA. p. 22-4.

- Tabatabaei M, Ghanavati H. Biogas: fundamentals, process, and operation. In: Prominent Parameters in Biogas Production Systems. Cham: Springer; 2018.

- Sreekanth KM, Sahu D. Effect of iron oxide nanoparticle in bio digestion of a portable food-waste digester. J Chem Pharm Res 2015; 7(9):353-9. [ Google Scholar]

- Chandra R, Takeuchi H, Hasegawa T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew Sustain Energy Rev 2012; 16(3):1462-76. doi: 10.1016/j.rser.2011.11.035 [Crossref] [ Google Scholar]

- Elaiyaraju P, Partha N. Biogas production from co-digestion of orange peel waste and Jatropha de-oiled cake in an anaerobic batch reactor. Afr J Biotechnol 2012; 11(14):3339-45. doi: 10.5897/ajb11.2622 [Crossref] [ Google Scholar]

- Khanal SK. Overview of anaerobic biotechnology. In: Anaerobic Biotechnology for Bioenergy Production: Principles and Applications. John Wiley & Sons; 2008. p. 385-406.

- Schmidt T. Schmidt TAnaerobic digestion of Jatropha curcas Lpress cake and effects of an iron-additive. Waste Manag Res 2011; 29(11):1171-6. doi: 10.1177/0734242x11425566 [Crossref] [ Google Scholar]