Avicenna J Environ Health Eng. 8(2):102-109.

doi: 10.34172/ajehe.2021.13

Original Article

The Use of Verbascum Thapsus L as a Biomembrane for Activated Sludge Filtration

Mohammed Saleh 1, Hudaverdi Arslan 1, Zelal Isik 1, Mutlu Yalvac 1, Nadir Dizge 1, *

Author information:

1Department of Environmental Engineering, Mersin University, Mersin, Turkey

Abstract

Membrane technology is a green technology, but it still faces a pressing problem related to the effect of fabrication materials on the environment. The plant Verbascum thapsus L (VTL) was utilized as a biomembrane to reduce chemicals. In this study, VTL was successfully utilized as a membrane for activated sludge separation. The membrane was characterized via scanning electron microscopy (SEM)-EDX, Fourier transform infrared (FTIR), and contact angle measurement. Additionally, the effects of pressures on the fluxes and the rejection ability were studied. The permeability of the bio-based membrane reached 581 L/m2.h.bar. The VTL membrane was examined for the removal of chemical oxygen demand (COD), protein, and carbohydrate. Accordingly, the maximum COD removal was obtained at a transmembrane pressure of 2.5 bar and reached up to 57%. The protein and carbohydrates rejections raised from 80% and 84% at 0.5 bar to 90% and 98% at 2.5 bar, respectively. The total resistance increased from 87% at a pressure of 0.5 bar to 96% at 2.5 bar. The flux recovery ratio (FRR) for the membrane at working pressures (0.5-2.5 bar) was 96% for 0.5 bar and 70% for 2.5 bar. The physical cleaning showed a flux recovery after three operation cycles. At the end of the filtration experiments, the pressure variation along streamlines over the membrane cross-section was simulated. As a result of this study, the use of a naturally-derived membrane is considered a green technology. The plant-based membrane reduces the use of non-green chemicals. Moreover, VTL has no commercial value and is recognized as an invasive plant species. All of the previous issues made the study worthwhile.

Keywords: Verbascum thapsus, Bio-membrane, Green membrane, Activated sludge filtration

Copyright and License Information

© 2021 The Author(s); Published by Hamadan University of Medical Sciences.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (

http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium provided the original work is properly cited.

1. Introduction

Water is the most valuable substance that is involved in all life activities (1). The water demand increased in the last centuries due to the sharp growth in population, the industrial revolution, and commercial development (2). As a result, the generation of wastewater has also increased. In this context, the need for safe disposal from the generated wastewater has become an urgent issue (3). Wastewater treatment aims to recover water with standard limits before discharging it to the environment (4). In general, the treatment method is classified into physical, chemical, biological, or a combination thereof (5). The physical forces are the predominant forces in the physical treatment units. The typical physical methods are screening, mixing, sedimentation, filtration, and adsorption (6). Membrane technology has become more attractive than conventional separation techniques (7,8) due to high efficiency (9), small area requirements (10), and ease of operation (11).

The membrane technology employs a semipermeable material to separate components (12). It can also be described as a selective barrier between two adjacent phases that regulates the movement of some constituents from one side to another (13). Membrane technology has been utilized in many fields. For example, Dizge et al used a cellulose membrane for drinking water treatment (14). Collivignarelli et al removed non-ionic and anionic surfactants from laundry wastewater (15), and Romero-Dondiz et al employed ultrafiltration and nanofiltration membranes for wastewater recovery in leather industry (16). The membrane is also employed in biodiesel purification (17), fermentation industry (18), gas separation (19), and food industry processes (20).

Even though membrane technology is considered a green technology (14), it still faces a pressing problem related to the effect of fabrication materials on the environment (21,22). To overcome this issue, many researchers have developed green membranes from natural sources. Saleh et al prepared ceramic membranes from basalt rock (23). Aloulou et al utilized Tunisian natural sand in a ceramic membrane preparation (24). Natural clay (25), fly ash (26), zeolite (27), and phosphate sub-products (28) were used as primary materials for membranes synthesis. Bio-derived solvents were also utilized in the preparation of polymeric membranes (22,29,30).

Nature has inspired many researchers to use materials present in it. Correa and Sens studied the possibility of utilizing wood as a membrane (31). Sens et al successfully employed a helical cross-flow filtration system to achieve an average removal of 70% and apparent color removal of 93% for average turbidity (32). Boutilier et al developed an effective point-of-use device from plant xylem to supply pathogen-free drinking water (33).

Verbascum thapsus L (VTL) is a plant that grows in many regions all over the world (34). At the bottom of the plant, there is a large rosette of leaves where the stem grows to reach 2 m or more (35). Its small yellow flowers are densely grouped on a tall stem (36). The presence of oil, glycoside, flavonoids, sesquiterpenes, and verbathasin A made the researchers use the plant in medical practices (37). The plant has limited applications in environmental engineering (38). In Turkey, the plant is unfavorable and classified as an invasive plant species. The farmers remove VTL from their farms by the physical method. Consequently, the accumulated plant wastes are burned near the fields. In this study, VTL was used as a biomembrane for activated sludge filtration. The ability of VTL membrane in removal of COD, protein, and carbohydrate was examined. At the end of the filtration experiments, the pressure variation among streamlines over the membrane cross-section was simulated. From different perspectives, the use of a naturally-derived membrane is considered a green application. The plant-based membrane reduces the use of non-green chemicals. Additionally, VTL has no commercial value and is recognized as an invasive plant species. All of the previous issues made the study worthwhile.

2. Materials and Methods

2.1. Preparation of Plant-Based Biomembrane

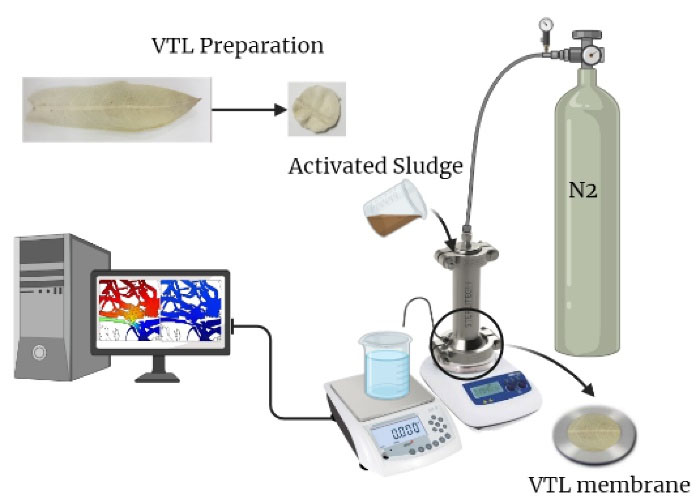

VTL was collected from farms within the boundaries of Erdemli district, Mersin, Turkey. The leaf of the plant was separated from the whole plant. VTL leaves were gently washed with distilled water to remove any dust residuals and dried at room temperature for 48 hours. VTL leaves were cut in a circular shape with a diameter of 5.2 cm and used as a bio-membrane in a dead-end filtration system, as shown in Fig. 1.

Figure 1.

A Schematic Diagram of the Bio-membrane System Applied in This Study.

.

A Schematic Diagram of the Bio-membrane System Applied in This Study.

2.2. Filtration Experiments of Activated Sludge

In this research study, the filtration experiments were accomplished, as discussed in the previous work (39), with some modifications. Briefly, the prepared membrane was supported by a porous steel disk and inserted in a dead-end filtration apparatus (Sterlitech HP 4750, Sterlitech, Kent, WA, USA). The distilled water was passed through the membrane under different pressure values (0.5-2.5 bar) using N2 gas at room temperature. The operating pressure was selected based on the preliminary studies to avoid any damages to the biomembrane. The water passed through the membrane was measured, and the permeate flux (Jw) was calculated using equation 1 (40,41).

where Jw is the permeate flux (L/m2h), V is the volume of the water passed through the membrane (L), A is the active surface area (m2), t is the time (t), ∆P is the differential pressure across the membrane (bar), µ is the fluid dynamic viscosity (kg/m.s), and Km is the membrane resistance coefficient (1/m).

The activated sludge was also filtrated, and the flux of permeate was recorded in the same manner as the distilled water flux. The used activated sludge was supplied from a local domestic wastewater treatment plant. The activated sludge characteristics included mixed liquor suspended solids concentration of 4500±150 mg/L, pH of 7.2±0.2, chemical oxygen demand (COD) of 323±5 mg/L, protein concentration of 58±4 mg/L, and carbohydrate concentration of 86±0.5 mg/L. The permeate water from the activated sludge filtration experiments was characterized, and the rejection percentage in the COD, protein, and carbohydrate was calculated using equation 2 (39).

(2)

2.3. Characterization of Plant-Based Membrane

The plant-based membrane was characterized using Scanning Electron Microscopy and. Energy Dispersive X-Ray Analysis (SEM-EDX, Zeiss Supra 55 Germany). The membranes were frozen with nitrogen, and a chromium layer was used to coat the membranes. SEM images and SEM-EDX were used to explore the surface morphology and the chemical composition of the membrane. Fourier Transform Infrared Spectroscopy (FTIR, PerkinElmer USA) was used to record the membrane spectrum in the range 400-4000 cm-1. Water contact angle measurement was carried out using a goniometer (One Attension, Biolin scientific instrument).

2.4. Model Development

The hydrodynamic part of the filtration process was modeled using the Darcy equations for the fluid flow in the porous material. COMSOL Multiphysics V 5.5 was used as a simulator software. Equation 3 shows the Darcy equation used in the model (42).

where u is the velocity of the fluid flow through the porous material (m/s), K, µ(c), and P are the permeability (m2), the dynamic viscosity (Pa/s), and the gradient in the pressure (Pa), respectively.

For the boundary conditions, the liquid was chosen to be distilled water with a density of 1000 kg/m3 and a dynamic viscosity of 1.002×10-3. SEM image was used as a basis to represent the porous material. Firstly, it was converted to binary format using Image J software and then exported to COMSOL Multiphysics. The input pressure was selected to be the same as the operating pressure (0.5-2.5 bar). The pressure at the output side was selected to be zero. The rest of the boundaries were selected to be a wall with no-slip conditions. To have significant results, the model was made of small triangle meshes. The change in pressure over the cross-section of the plant and the water streamline were determined.

3. Results and Discussion

3.1. Characterization of Plant-Based Membrane

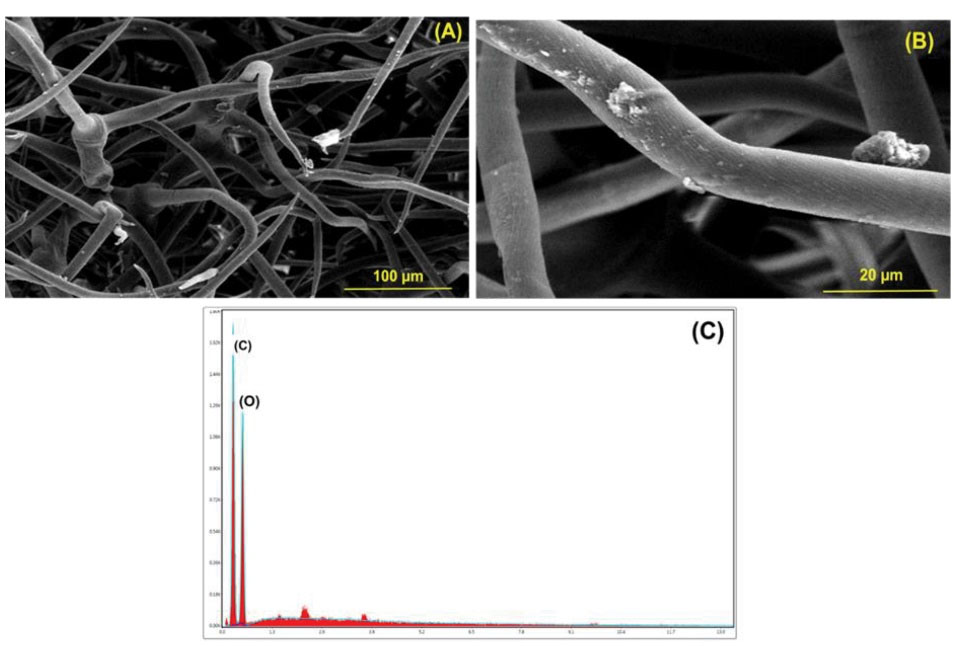

The morphology of the bio-based membrane was characterized. The membranes have a neural network shape. The network consists of a number of nodes that comprised start points for cylindrical rods with different lengths and sizes (Fig. 2A and B). SEM-EDX analysis was also done. The plant-based membrane is formed from 48.15% carbon and 51.85% oxygen by weight. The obtained results for SEM-EDX are shown in Fig. 2C.

Figure 2.

SEM Images for (A) VTL (100 µm), (B) VTL (20 µm), (C) SEM-EDX Results.

.

SEM Images for (A) VTL (100 µm), (B) VTL (20 µm), (C) SEM-EDX Results.

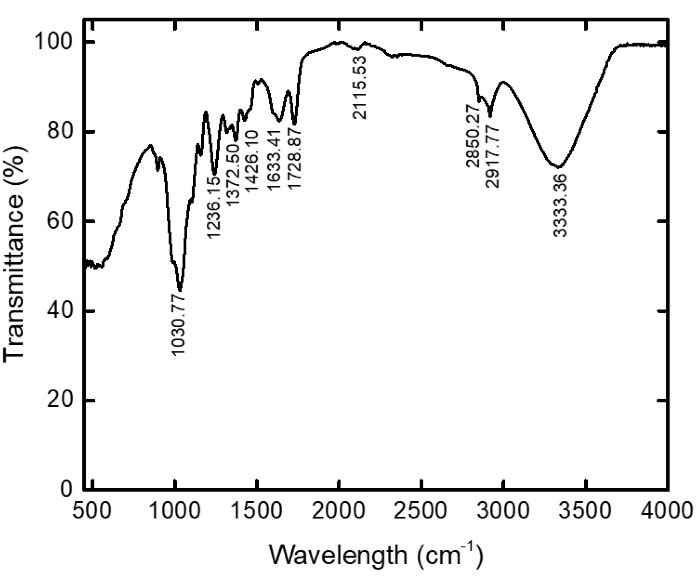

The functional groups present on the VTL surface were recorded using Fourier Transform Infrared Spectroscopy (FT/IR-6700, Jasco) and are shown in Fig. 3. The peaks extended over five bands reflect that the sample may be a complex molecule. The presence of a peak at a band 3333.36 cm-1, which is located in the range 3200-3600 cm-1 refers to hydrogen bond O-H stretching (43). The recorded peaks under 3000 cm-1 indicate the presence of aliphatic compounds. The functional group, C-H stretch for CH2 and CH3 groups, was noticed at 2850.27 and 2917.77 cm-1bands. The mono distributed alkyne with C= C stretch was recorded at 2115.53 cm-1 (44,45). The carbonyl compounds (aldehydes) were noticed at the functional group, C=C stretch, at the band of 1728.87 cm-1. The conjugated alkene class, which was attributed to C=C stretching, was noticed near 1633.41 cm-1. Johar et al recorded strong peak at 1623.77cm-1 and related it to the H-O-H bending (46). The peaks at the bands 1426.10 and 1372.50 cm-1 may correspond to O-H functional group. The strong peak at 1030.77 cm-1 may be related to sulfoxide class with functional group, S=O stretch. Yalvaç et al recorded similar results for VTL (38).

Figure 3.

FTIR Spectrum for VTL Membrane.

.

FTIR Spectrum for VTL Membrane.

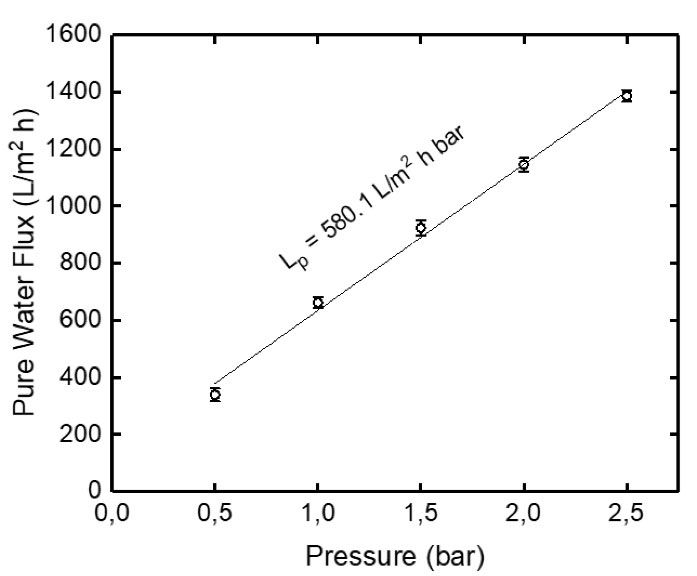

3.2. Plant-Based Membrane Permeability for Distilled Water

The permeability of the plant-based membrane was determined by measuring the distilled water passed through the membrane under different transmembrane pressure. Water flux increased at higher transmembrane pressure from 339 L/m2h at 0.5 bar to 1387 L/m2h at 2.5 bar. The permeability of the plant-based membrane reached 580 L/m2hbar, and the membrane resistance coefficient was 5.8×1011m-1. Similar results were obtained in previous studies (47,48). The linearity between the pressure and the water flux is shown in equation 1, and Fig. 4 infers that the flux can reach the maximum values at the highest potential transmembrane pressure. The water contact angle for the VTL plant was found to be 112±2°. According to Cheryan, the above-mentioned result is valid for the distilled water only where the risk of fouling is negligible. In the case of natural water/wastewater, the operation at higher pressure may exacerbate the membrane fouling (49).

Figure 4.

Distilled Water Flux at Distinct Pressure Values.

.

Distilled Water Flux at Distinct Pressure Values.

3.3. Effect of the Operating Pressure on the Rejection and the Permeate Flux

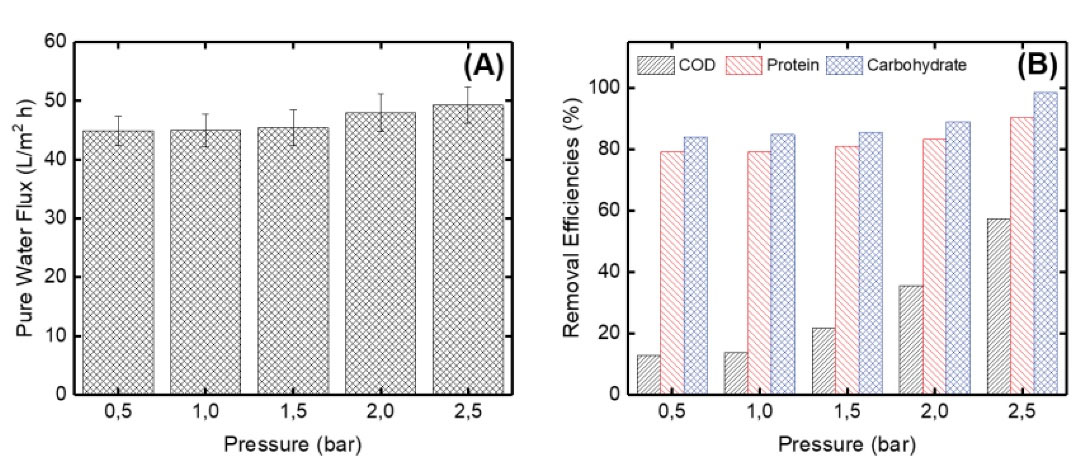

The fluxes of the plant-based membrane at different transmembrane pressures (0.5-2.5 bar) were recorded and shown in Fig. 5A. The fluxes at the steady state were convergent, but in general, the fluxes increased with the increases in the pressure. The steady-state flux was 45 L/m2h at 0.5 bar, while the flux at 2.5 bar reached 50 L/m2h. The membrane capabilities in the COD, protein, and carbohydrate reduction at different operational pressures were also explored (Fig 5B). Accordingly, the maximum COD removal was obtained at a transmembrane pressure of 2.5 bar and reached 57%. The minimum rejection was 13% at a pressure of 0.5 bar. For the protein and carbohydrate rejection, the membrane showed high rejection performance at all operating pressures. In both, the rejection increased with the increases in the applied pressure. The protein rejection raised from 80% at 0.5 bar to 90% at 2.5 bar. The rejection of protein showed a low increment at pressures 1.0, 1.5, and 2.0 bar. The rejection of carbohydrates increased slowly with the increases in the pressure (from 84% at 0.5 bar to 89% at 2 bar). Then, the removal increased to reach 98% at 2.5 bar.

Figure 5.

(A) Inclination-dependent Flux Profile for the Activated Sludge Under Different Pressure Values, (B) COD, Protein, and Carbohydrate Removal Efficiencies Under Different Pressure Values.

.

(A) Inclination-dependent Flux Profile for the Activated Sludge Under Different Pressure Values, (B) COD, Protein, and Carbohydrate Removal Efficiencies Under Different Pressure Values.

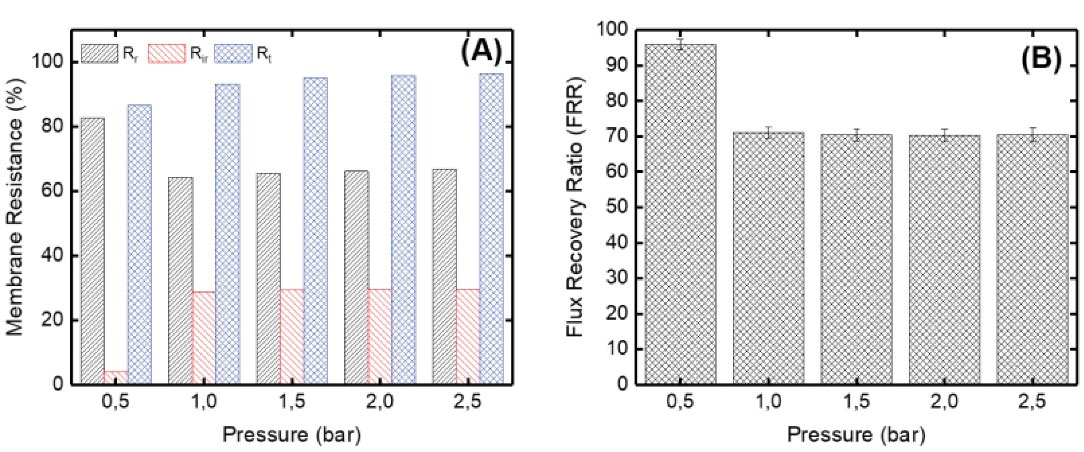

3.4. Plant-Based Membrane Fouling Resistance and Flux Recovery

The hydraulic resistance for the membrane due to the fouling aspect manifested as a decline in the permeate flux in the case of fixed operation pressure. Or as an increment in the transmembrane pressure in case of constant permeate flux(50). The total fouling resistance (Rt) may be divided into reversible (Rr) and irreversible resistance (Rir) (51). Fig. 6A shows the total, reversible, and irreversible fouling resistance at different transmembrane pressures. The total resistance increased from 87% at a pressure value of 0.5 bar to 96% at 2.5 bar. The irreversible resistance (Rir) at a pressure of 0.5 bar was at the minimum level (4%), while the reversible resistance (Rr) was at the maximum level (83%). In contrast, Rir and Rr almost were 30% and 66% at an operational pressure of 2.5 bar.

Figure 6.

(A) Fouling Resistance for the Activated Sludge Under Different Pressure Values (B) Flux Recovery Rate for the Activated Sludge Under Different Pressure Values.

.

(A) Fouling Resistance for the Activated Sludge Under Different Pressure Values (B) Flux Recovery Rate for the Activated Sludge Under Different Pressure Values.

The flux recovery ratios (FRRs) for the membrane at working pressures (0.5-2.5) were calculated by obtaining the flux at the end of the filtration experiments. Fig. 6B shows the recovery of the flux at the pressure of 0.5-2.5 bar. Accordingly, FRR had an inverse relationship with the transmembrane pressure. At lower pressure values (0.5 bar), FRR was approximated to be 96%, while the values decreased to reach 70% at the pressure of 2.5 bar.

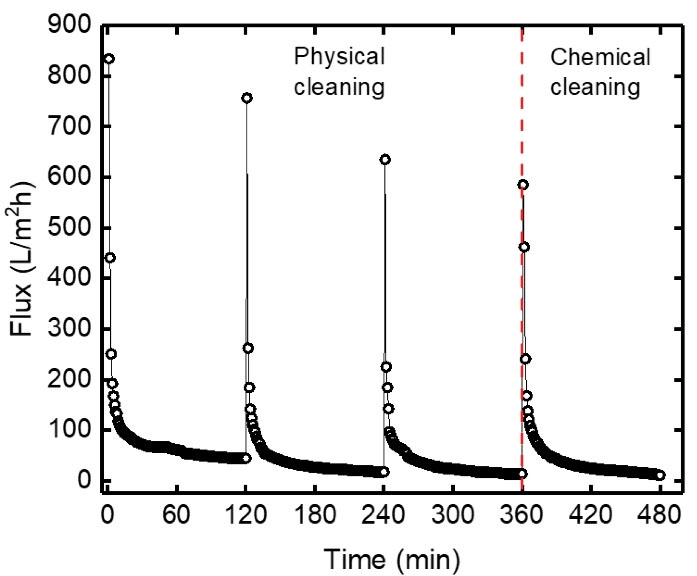

3.5. Physical and Chemical Cleaning of Biomembrane

The fluxes declined in three stages. For the first 10 minutes, fluxes decreased rapidly, followed by gradual flux decreases to reach the steady state. The membrane pore blocking is the mechanism that causes rapid initial drop, which incremented with the increases in the applied differential pressure (52). After that stage, the cake layer formation at the membrane surface demonstrated additional permeate flux resistance, followed by gradual inclination over the filtration time (53).

Membrane cleaning is a way to recover the flux and eliminate fouling of the membranes. The cleaning was carried out using physical and chemical cleaning methods. According to Katsoufidou et al, physical cleaning is the simplest way to recover the flux (54). However, the flux may not be recovered by the physical cleaning alone (55). Chemical cleaning should be applied to remove the organic and inorganic materials, which cannot be removed via physical cleaning (56). In this study, physical cleaning was firstly applied by distilled water filtration for 10 minutes. Then, the plant-based membrane was cleaned chemically using 0.1 M sodium hydroxide followed by distilled water. Subsequently, activated sludge was filtered again for 120 minutes. The physical cleaning showed a flux recovery after three operation cycles. The initial and steady-state fluxes were 695 and 20 L/m2h, respectively. The flux recovery after chemical cleaning was the same after physical cleaning. The initial flux after the chemical cleaning was 585 L/m2h and gradually dropped to reach 14.8 L/m2h at the end of the filtration experiments (Fig. 7).

Figure 7.

Effects ofPhysical and Chemical Cleaning on the Flux Recovery.

.

Effects ofPhysical and Chemical Cleaning on the Flux Recovery.

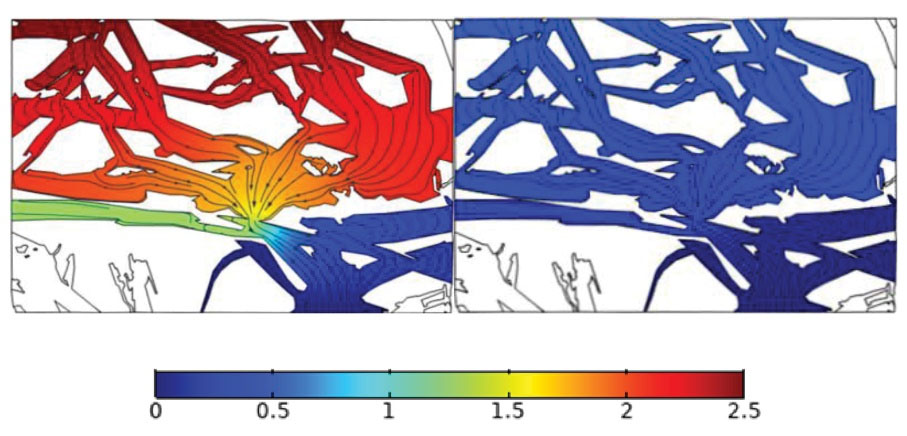

3.6. Model Results

The streamlines of the water flow through the plant-based membrane are shown in Fig. 8. The streamlines flow from the inlet to the outlet. According to the SEM images of the plant-based membrane sample, the water is collected at specific points where the flow rate is greater and the membrane is present in two locations. The pressure gradient through the membrane exposed to the pressure of 2.5 bar is larger than the pressure gradient for the same membrane under the pressure of 0.5 bar (Fig. 8). explained the increase in flux with the pressure increase.

Figure 8.

Pressure gradient and the stream line at 2.5 bar (Left side) and 0.5 bar (right side) over the plant-based membrane.

.

Pressure gradient and the stream line at 2.5 bar (Left side) and 0.5 bar (right side) over the plant-based membrane.

3.7. Comparison with other Biomembranes

The prepared VTL membrane was compared with other biomembranes. Different types of membranes were used in separation of different types of materials. Table 1 shows the biomembrane application.

Table 1.

Comparison Between Different Types of Biomembranes

|

Membrane

|

Application

|

Efficiency

|

Reference

|

| VTL based- membrane |

Activated sludge (removal of COD, protein, and carbohydrate) |

COD: 57%

Protein: 90%

Carbohydrate:98% |

This study |

|

Aspergillus carbonariusM333 |

Textile wastewater |

Color: 91% |

(48) |

| Bio-based polymers fabricated from isosorbide-incorporated poly (arylene ether)s |

Water treatment |

BSA >99% |

(57) |

| Bio-derived ultrathin membrane |

Solar-driven water purification |

Organic pollutant >99.8% |

(58) |

| Bio-ceramic hollow fiber membranes prepared from cow bone waste |

Future perspective: seawater desalination |

- |

(59) |

| Bio-inspired membrane with adaptable wettability |

Oil/water separation |

Oil purity >99% |

(60) |

4. Conclusion

In this study, VTL was successfully utilized as a membrane for activated sludge separation. Based on the SEM images, the membranes have a neural network shape. The network consisted of a number of nodes, which comprised start points for cylindrical rods with different lengths and sizes. The VTL-based membrane was examined for the removal of COD, protein, and carbohydrate. The plant-based membrane showed a high performance in activated sludge separation, especially in protein and carbohydrate rejection. The total resistance increased from 87% at 0.5 bar to 96% at 2.5 bar. The FRR for the membrane was 70% at 2.5 bar. The physical cleaning showed a flux recovery after three operation cycles without needing any chemicals. Additionally, the pressure gradient over the plant-based membrane cross-section was modeled. The utilization of the plant as a membrane can be considered as an eco-friendly application from different perspectives. The first one is to reduce the chemicals needed in the membrane fabrication process, which leads to a reduction in the cost. Moreover, the use of plants with no commercial value may reduce the air pollution that originated from similar plant burning. However, the plant-based membranes still need further researches before entering the application stage from sustainability and durability aspects. In addition, the synthesis of nanomaterials should be studied to increase efficiency.

Acknowledgement

The authors acknowledge that the study is a part of the thesis entitled “investigation of beneficial uses of some agricultural and industrial solid wastes in wastewater treatment”.

Conflict of Interest Disclosures

The authors declare that there are no known conflicts of interest associated with this publication.

References

- Saleh M, Yalvaç M, Sime F. Rainfall-runoff model for Mersin University campus, Mersin. In: 4th International Water Congress; İzmir, Turkey; 2017.

- Zobeidi T, Yazdanpanah M, Forouzani M, Khosravipour B. Climate change discourse among Iranian farmers. Clim Change 2016; 138(3-4):521-35. doi: 10.1007/s10584-016-1741-y [Crossref] [ Google Scholar]

- Saleh M, Bilici Z, Ozay Y, Yabalak E, Yalvac M, Dizge N. Green synthesis of Quercus coccifera hydrochar in subcritical water medium and evaluation of its adsorption performance for BR18 dye. Water Sci Technol 2021; 83(3):701-14. doi: 10.2166/wst.2020.607 [Crossref] [ Google Scholar]

- López-Maldonado EA, Hernández-García H, Zamudio-Aguilar MAM, Oropeza-Guzmán MT, Ochoa-Terán A, López-Martínez LM. Chemical issues of coffee and Tule lignins as ecofriendly materials for the effective removal of hazardous metal ions contained in metal finishing wastewater. Chem Eng J 2020; 397:125384. doi: 10.1016/j.cej.2020.125384 [Crossref] [ Google Scholar]

- Davis ML. Water and Wastewater Engineering: Design Principles and Practice. New York: McGraw-Hill; 2010.

- Metcalf L, Eddy HP. Sewerage and Sewage Disposal. New York: McGraw-Hill; 1992.

- Brunetti A, Scura F, Barbieri G, Drioli E. Membrane technologies for CO2 separation. J Memb Sci 2010; 359(1):115-25. doi: 10.1016/j.memsci.2009.11.040 [Crossref] [ Google Scholar]

- He X, Hägg MB. Membranes for environmentally friendly energy processes. Membranes (Basel) 2012; 2(4):706-26. doi: 10.3390/membranes2040706 [Crossref] [ Google Scholar]

- Wang P, Chung TS. Recent advances in membrane distillation processes: Membrane development, configuration design and application exploring. J Memb Sci 2015; 474:39-56. doi: 10.1016/j.memsci.2014.09.016 [Crossref] [ Google Scholar]

- Ahmad S, Ahmed SM. Application of membrane technology in food processing. In: Malik A, Erginkaya Z, Ahmad S, Erten H, eds. Food Processing: Strategies for Quality Assessment. New York, NY: Springer; 2014. p. 379-94. 10.1007/978-1-4939-1378-7_15.

- Ciardelli G, Corsi L, Marcucci M. Membrane separation for wastewater reuse in the textile industry. Resour Conserv Recycl 2001; 31(2):189-97. doi: 10.1016/s0921-3449(00)00079-3 [Crossref] [ Google Scholar]

- Crittenden JC, Trussell RR, Hand DW, Howe KJ, Tchobanoglous G. MWH’s Water Treatment: Principles and Design. 3rd ed. New Jersey: John Wiley & Sons; 2012.

- Ulbricht M. Advanced functional polymer membranes. Polymer 2006; 47(7):2217-62. doi: 10.1016/j.polymer.2006.01.084 [Crossref] [ Google Scholar]

- Dizge N, Shaulsky E, Karanikola V. Electrospun cellulose nanofibers for superhydrophobic and oleophobic membranes. J Memb Sci 2019; 590:117271. doi: 10.1016/j.memsci.2019.117271 [Crossref] [ Google Scholar]

- Collivignarelli MC, Carnevale Miino M, Baldi M, Manzi S, Abbà A, Bertanza G. Removal of non-ionic and anionic surfactants from real laundry wastewater by means of a full-scale treatment system. Process Saf Environ Prot 2019; 132:105-15. doi: 10.1016/j.psep.2019.10.022 [Crossref] [ Google Scholar]

- Romero-Dondiz EM, Almazán JE, Rajal VB, Castro-Vidaurre EF. Comparison of the performance of ultrafiltration and nanofiltration membranes for recovery and recycle of tannins in the leather industry. J Clean Prod 2016; 135:71-9. doi: 10.1016/j.jclepro.2016.06.096 [Crossref] [ Google Scholar]

- Torres JJ, Rodriguez NE, Arana JT, Ochoa NA, Marchese J, Pagliero C. Ultrafiltration polymeric membranes for the purification of biodiesel from ethanol. J Clean Prod 2017; 141:641-7. doi: 10.1016/j.jclepro.2016.09.130 [Crossref] [ Google Scholar]

- Sun J, Mao X. An environmental friendly process for Antarctic krill (Euphausia superba) utilization using fermentation technology. J Clean Prod 2016; 127:618-23. doi: 10.1016/j.jclepro.2016.04.020 [Crossref] [ Google Scholar]

- Rezakazemi M, Sadrzadeh M, Matsuura T. Thermally stable polymers for advanced high-performance gas separation membranes. Prog Energy Combust Sci 2018; 66:1-41. doi: 10.1016/j.pecs.2017.11.002 [Crossref] [ Google Scholar]

- Nazir A, Khan K, Maan A, Zia R, Giorno L, Schroën K. Membrane separation technology for the recovery of nutraceuticals from food industrial streams. Trends Food Sci Technol 2019; 86:426-38. doi: 10.1016/j.tifs.2019.02.049 [Crossref] [ Google Scholar]

- Ji D, Xiao C, An S, Zhao J, Hao J, Chen K. Preparation of high-flux PSF/GO loose nanofiltration hollow fiber membranes with dense-loose structure for treating textile wastewater. Chem Eng J 2019; 363:33-42. doi: 10.1016/j.cej.2019.01.111 [Crossref] [ Google Scholar]

- Marino T, Galiano F, Molino A, Figoli A. New frontiers in sustainable membrane preparation: CyreneTM as green bioderived solvent. J Memb Sci 2019; 580:224-34. doi: 10.1016/j.memsci.2019.03.034 [Crossref] [ Google Scholar]

- Saleh M, Gonca S, Isik Z, Ozay Y, Harputlu E, Ozdemir S. Preparation of ZnO nanorods or SiO2 nanoparticles grafted onto basalt ceramic membrane and the use for E coli removal from water. Ceram Int 2021; 47(19):27710-7. doi: 10.1016/j.ceramint.2021.06.196 [Crossref] [ Google Scholar]

- Aloulou H, Bouhamed H, Amar RB, Khemakhem S. New ceramic microfiltration membrane from Tunisian natural sand: Application for tangential waste water treatment. Desalin Water Treat 2017; 78:41-8. doi: 10.5004/dwt.2017.20921 [Crossref] [ Google Scholar]

- Hubadillah SK, Dzarfan Othman MH, Matsuura T, Ismail AF, Rahman MA, Harun Z. Fabrications and applications of low cost ceramic membrane from kaolin: a comprehensive review. Ceram Int 2018; 44(5):4538-60. doi: 10.1016/j.ceramint.2017.12.215 [Crossref] [ Google Scholar]

- Suresh K, Pugazhenthi G, Uppaluri R. Fly ash based ceramic microfiltration membranes for oil-water emulsion treatment: Parametric optimization using response surface methodology. J Water Process Eng 2016; 13:27-43. doi: 10.1016/j.jwpe.2016.07.008 [Crossref] [ Google Scholar]

- Feng C, Khulbe KC, Matsuura T, Farnood R, Ismail AF. Recent progress in zeolite/zeotype membranes. J Membr Sci Res 2015; 1(2):49-72. doi: 10.22079/jmsr.2015.13530 [Crossref] [ Google Scholar]

- Khemakhem M, Khemakhem S, Ayedi S, Cretin M, Ben Amar R. Development of an asymmetric ultrafiltration membrane based on phosphates industry sub-products. Ceram Int 2015; 41(9 Pt A):10343-8. doi: 10.1016/j.ceramint.2015.05.101 [Crossref] [ Google Scholar]

- Huang Y, Huang Q, Liu H, Xiao C, Sun K. A facile and environmental-friendly strategy for preparation of poly (tetrafluoroethylene-co-hexafluoropropylene) hollow fiber membrane and its membrane emulsification performance. Chem Eng J 2020; 384:123345. doi: 10.1016/j.cej.2019.123345 [Crossref] [ Google Scholar]

- Kamali M, Suhas DP, Costa ME, Capela I, Aminabhavi TM. Sustainability considerations in membrane-based technologies for industrial effluents treatment. Chem Eng J 2019; 368:474-94. doi: 10.1016/j.cej.2019.02.075 [Crossref] [ Google Scholar]

- Correa E, Sens ML. Water Filtration in Wood Membrane, Completion of Coursework. UFSC, Floriano´polis, SC; 2002. p. 23-30.

- Sens ML, Emmendoerfer ML, Muller LC. Water filtration through wood with helical cross-flow. Desalin Water Treat 2015; 53(1):15-26. doi: 10.1080/19443994.2013.837010 [Crossref] [ Google Scholar]

- Boutilier MS, Lee J, Chambers V, Venkatesh V, Karnik R. Water filtration using plant xylem. PLoS One 2014; 9(2):e89934. doi: 10.1371/journal.pone.0089934 [Crossref] [ Google Scholar]

- Murti K, Singh R, Paliwal D, Taya P, Divya S. Effect of Verbascum thapsus L on normal and dexamethasone suppressed wound healing. Pharmacologyonline 2011; 2:684-97. [ Google Scholar]

- Kalalian-Moghaddam H, Mirzaii M, Khaksari M, Fazli M, Rahimi F, Amiri Behzadi A. Antibacterial and anti-adherent activity of great mullein (Verbascum thapsus L) ethanolic extract on in vitro biofilm formation of three oral streptococci. Int J Health Stud 2015; 1(2):34-7. doi: 10.22100/ijhs.v1i2.64 [Crossref] [ Google Scholar]

- Hussain H, Aziz S, Miana GA, Ahmad VU, Anwar S, Ahmed I. Minor chemical constituents of Verbascum thapsus. Biochem Syst Ecol 2009; 37(2):124-6. doi: 10.1016/j.bse.2008.12.007 [Crossref] [ Google Scholar]

- Elemike EE, Onwudiwe DC, Mkhize Z. Eco-friendly synthesis of AgNPs using Verbascum thapsus extract and its photocatalytic activity. Mater Lett 2016; 185:452-5. doi: 10.1016/j.matlet.2016.09.026 [Crossref] [ Google Scholar]

- Yalvaç M, Arslan H, Saleh M, Gün M, Hekim MŞ. Utilizing of bio-adsorbent in zero waste concept: adsorption study of crystal violet onto the Centaurea solstitialis and Verbascum thapsus plants. Pamukkale Univ J Eng Sci 2020; 27(3):349-58. [ Google Scholar]

- Saleh M, Ozay Y, Yalvac M, Dizge N. Preparation of composite polyethersulfone membrane containing basalt powder and optimization of the parameters using response surface methodology. Environ Technol. 2021:1-11. 10.1080/09593330.2021.1923818.

- Alias SS, Harun Z, Latif ISA. Characterization and performance of porous photocatalytic ceramic membranes coated with TiO2 via different dip-coating routes. J Mater Sci 2018; 53(16):11534-52. doi: 10.1007/s10853-018-2392-3 [Crossref] [ Google Scholar]

- Hossain MM, Wu L, Li Y, Ge L, Xu T. Preparation of porous poly(vinylidene fluoride) membranes with acrylate particles for electrodialysis application. Sep Purif Technol 2015; 150:102-11. doi: 10.1016/j.seppur.2015.06.020 [Crossref] [ Google Scholar]

- Nield DA, Bejan A. Convection in Porous Media. New York: Springer Science+Business Media; 2006.

- Srivastava AK, Kaundal B, Sardoiwala MN, Choudhury SR, Karmakar S. Coupled catalytic dephosphorylation and complex phosphate ion-exchange in networked hierarchical lanthanum carbonate grafted asymmetric bio-composite membrane. J Colloid Interface Sci 2022; 606(Pt 2):2024-37. doi: 10.1016/j.jcis.2021.09.173 [Crossref] [ Google Scholar]

- Rosa SML, Rehman N, de Miranda MIG, Nachtigall SMB, Bica CID. Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohydr Polym 2012; 87(2):1131-8. doi: 10.1016/j.carbpol.2011.08.084 [Crossref] [ Google Scholar]

- Proniewicz LM, Paluszkiewicz C, Wesełucha-Birczyńska A, Majcherczyk H, Barański A, Konieczna A. FT-IR and FT-Raman study of hydrothermally degradated cellulose. J Mol Struct 2001; 596(1):163-9. doi: 10.1016/s0022-2860(01)00706-2 [Crossref] [ Google Scholar]

- Johar N, Ahmad I, Dufresne A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind Crops Prod 2012; 37(1):93-9. doi: 10.1016/j.indcrop.2011.12.016 [Crossref] [ Google Scholar]

- Boussemghoune M, Chikhi M, Balaska F, Ozay Y, Dizge N, Kebabi B. Preparation of a zirconia-based ceramic membrane and its application for drinking water treatment. Symmetry 2020; 12(6):933. doi: 10.3390/sym12060933 [Crossref] [ Google Scholar]

- Isik Z, Arikan EB, Bouras HD, Dizge N. Bioactive ultrafiltration membrane manufactured from Aspergillus carbonarius M333 filamentous fungi for treatment of real textile wastewater. Bioresour Technol Rep 2019; 5:212-9. doi: 10.1016/j.biteb.2019.01.020 [Crossref] [ Google Scholar]

- Cheryan M. Ultrafiltration and Microfiltration Handbook. Lancaster, PA: Technomic; 1998.

- Salahi A, Abbasi M, Mohammadi T. Permeate flux decline during UF of oily wastewater: experimental and modeling. Desalination 2010; 251(1-3):153-60. doi: 10.1016/j.desal.2009.08.006 [Crossref] [ Google Scholar]

- Akar N, Asar B, Dizge N, Koyuncu I. Investigation of characterization and biofouling properties of PES membrane containing selenium and copper nanoparticles. J Memb Sci 2013; 437:216-26. doi: 10.1016/j.memsci.2013.02.012 [Crossref] [ Google Scholar]

- Hlavacek M, Bouchet F. Constant flowrate blocking laws and an example of their application to dead-end microfiltration of protein solutions. J Memb Sci 1993; 82(3):285-95. doi: 10.1016/0376-7388(93)85193-z [Crossref] [ Google Scholar]

- Kim AS, Hoek EM. Cake structure in dead-end membrane filtration: Monte Carlo simulations. Environ Eng Sci 2002; 19(6):373-86. doi: 10.1089/109287502320963373 [Crossref] [ Google Scholar]

- Katsoufidou K, Yiantsios SG, Karabelas AJ. A study of ultrafiltration membrane fouling by humic acids and flux recovery by backwashing: experiments and modeling. J Memb Sci 2005; 266(1-2):40-50. doi: 10.1016/j.memsci.2005.05.009 [Crossref] [ Google Scholar]

- Hong S, Elimelech M. Chemical and physical aspects of natural organic matter (NOM) fouling of nanofiltration membranes. J Memb Sci 1997; 132(2):159-81. doi: 10.1016/s0376-7388(97)00060-4 [Crossref] [ Google Scholar]

- Woo YC, Lee JJ, Oh JS, Jang HJ, Kim HS. Effect of chemical cleaning conditions on the flux recovery of fouled membrane. Desalin Water Treat 2013; 51(25-27):5268-74. doi: 10.1080/19443994.2013.768754 [Crossref] [ Google Scholar]

- Kim D, Kim IC, Kwon YN, Myung S. Novel bio-based polymer membranes fabricated from isosorbide-incorporated poly(arylene ether)s for water treatment. Eur Polym J 2020; 136:109931. doi: 10.1016/j.eurpolymj.2020.109931 [Crossref] [ Google Scholar]

- Han X, Wang W, Zuo K, Chen L, Yuan L, Liang J. Bio-derived ultrathin membrane for solar driven water purification. Nano Energy 2019; 60:567-75. doi: 10.1016/j.nanoen.2019.03.089 [Crossref] [ Google Scholar]

- Hubadillah SK, Othman MHD, Jamalludin MR, Naim R, Sheikh Abdul Kadir SH, Puteh MH. Fabrication and characterisation of superhydrophobic bio-ceramic hollow fibre membranes prepared from cow bone waste. Ceram Int 2021; 47(3):4178-86. doi: 10.1016/j.ceramint.2020.09.295 [Crossref] [ Google Scholar]

- Li L, Xu Z, Sun W, Chen J, Dai C, Yan B. Bio-inspired membrane with adaptable wettability for smart oil/water separation. J Memb Sci 2020; 598:117661. doi: 10.1016/j.memsci.2019.117661 [Crossref] [ Google Scholar]